As I was finishing the first draft of this story, the lights went off. The power to my house had failed. We checked the fuse box, found some bike lights to serve as torches, and my teenage daughter helped her little brother with his candlelit homework. My wife and I bored our offspring with tales of the power cuts we used to enjoy as children.

There were no macroeconomic forces behind this particular outage — a blown fuse at the substation was fixed within a couple of hours. It was, however, a little too on-brand for modern Britain.

The lights for the whole world’s economy seem to be flickering. Costs of container shipping have increased nearly tenfold since last summer, while major ports face serious congestion. German economists fear a “bottleneck recession” as the manufacturing powerhouse struggles to source raw materials. Car manufacturers have shelved production because they can’t get enough computer chips.

Yet while the wheels of the global economy seem to be coming off, the British economy is being scraped face-first across the economic tarmac. The shortage of truck drivers in many advanced economies is more acute in the UK since 14,000 EU citizens stopped working as lorry drivers between the summer of 2020 and the spring of 2021. Businesses have been warning for months that the Christmas surge in demand, for everything from turkeys to toys to sweets, simply cannot be satisfied.

The UK has suffered a shortage of fuel at petrol stations up and down the country. (It is never a good sign when the politicians call in the army.) While energy prices are rising around the world, Britain is particularly vulnerable to a rise in the price of gas, which also feeds into expensive electricity. About a dozen British energy retailers, supplying more than two million people, have already gone bust. A cold, costly winter is coming.

It wasn’t supposed to be like this. After last year’s pandemic-related shortages of masks and toilet paper and spaghetti subsided, supply chains were supposed to adapt. At first, the numbers suggested that the economy was adjusting — the UK’s second lockdown did far less economic damage than the first. We were getting through this; there was no reason to expect another winter of discontent. (It should be acknowledged that the original, in 1978-79, was rather different: a lorry drivers’ strike, a refuse collectors’ strike and even a gravediggers’ strike filled the front pages and put pressure on James Callaghan’s government. That winter has been a bruise on British politics ever since.)

So why do Britain’s shortages seem worse than ever? Is there anything we can do to ease the problem, in the UK and around the world? And — whisper it — is there a chance that all this chaos might just make us stronger?

In my first attempt to understand what is happening, I picked up János Kornai’s 1980 book, Economics of Shortage. Kornai gradually moved from being an ardent communist in postwar Hungary to a clear-eyed critic and analyst of the failings of central planning. He begins by declaring that his book is the first, to his knowledge, to focus exclusively on shortages. Will his work explain the shortage of petrol or carbon dioxide or power tools in 2021? It will not. “My study,” he explains in the text, “is centred on socialist economic systems.”

There is a reason that Kornai does little more than nod to the idea of a shortage in a market economy: they are not supposed to happen. Despite often being characterised as “the study of the allocation of scarce resources”, economics generally has little to say about actual shortages in a market economy.

In a planned economy, shortages result because prices do not move to reflect the forces of supply and demand. In a market economy, however, prices should adjust. If lots of people want petrol and there isn’t enough to go around, the price of petrol will naturally rise until the quantity demanded equals the quantity available.

In the textbooks, a “shortage” doesn’t mean dry pumps or empty shelves: it means that prices spike. They might double or triple. Some will find it impossibly expensive to drive, and others might find their finances ruined because they have no choice but to buy fuel they cannot really afford. But there are no queues; there is always petrol available to those who are willing and able to pay.

For some products and services, prices have indeed spiked. But consumers have so far been insulated from those increases. “Shipping costs have risen,” says Shanella Rajanayagam, a trade economist at HSBC. “But the price of imported goods has only ticked up slightly.”

Quite so. For retail consumers, our experience was not that the price of electricity, toilet paper or petrol doubled. It was that there was no petrol and no toilet paper. Power still flowed, but the electricity retailer who promised to keep it cheap had gone bankrupt.

In 1986, Daniel Kahneman, Jack Knetsch and Richard Thaler published an explanation of why prices do not shift in a crisis: customers hate it when they do. The researchers described simple scenarios to people and listened to their response. A large majority objected to businesses who raised the price of shovels the day after a blizzard, or charged extra for Red Delicious apples that were sold out everywhere else. Kahneman and his colleagues noted that when prices adjusted to balance supply and demand, economists viewed this process as “as natural as water finding its level — and as ethically neutral. The lay public does not share this indifference.”

Businesses know this. Tesco or BP could raise prices to ensure that there was always toilet paper on the shelf and petrol in the pump, but their customers would not thank them. A few days of extra profit are not worth the bad press. They would rather run out.

In the long term, prices usually do adjust. Customers who fume at overnight profiteering will tolerate slower shifts in price — and companies cannot afford to misprice products for ever. (Although sometimes it is nearly for ever: the price of a bottle of Coca-Cola was five cents in 1886 and remained so until the late 1950s.)

If markets are allowed to work, then, the shortages will disappear in the long run. But it is time for the obligatory John Maynard Keynes quote: “This long run is a misleading guide to current affairs. In the long run we are all dead. Economists set themselves too easy, too useless a task if in tempestuous seasons they can only tell us that when the storm is long past the ocean will be flat again.”

The central eight words of that quotation, from 1923’s A Tract on Monetary Reform, have been as widely quoted as anything he said. The context is often missing: Keynes was complaining about an economics that could study two different steady states, in each of which supply equalled demand, but had nothing to say about the tumultuous journey between them.

For a chirpy, free-market perspective on the whole affair, look no further than the star of a 1958 essay “I, Pencil . . . as Told to Leonard E. Read”.

The pencil, our loquacious narrator, knows it seems unassuming. “Pick me up and look me over. What do you see? Not much meets the eye — there’s some wood, lacquer, the printed labelling, graphite lead, a bit of metal, and an eraser.”

But the pencil is soon in an expansive mood as it describes its “family tree”. Collecting its cedar wood required axes and saws, motors and a railway. Its graphite is from Sri Lanka, mixed with Mississippi clay, sulphuric acid, animal fats and numerous other ingredients. The pencil is nothing short of lyrical on the topic of its ferrule, its eraser (made not of rubber, but rape seed oil, sulphur chloride and an abrasive pinch of Italian pumice), and its magnificent six (six!) coats of lacquer.

The stirring lesson of all this unappreciated complexity? “Leave all creative energies uninhibited . . . Have faith that free men and women will respond to the Invisible Hand. This faith will be confirmed.”

The pencil’s autobiography is a vivid account of the complexities of a market economy. But from the perspective of 2021, it is hard to read without thinking about disaster scenarios. What if floods prevent the quarrying of Mississippi clay? What if there is a shortage of pumice? What if all the rape seed oil is bought and bottled by the supermarkets? There are so many ways for the pencil’s fragile-seeming supply chain to snap.

In the late 1700s, the French pencil industry discovered exactly this. Graphite was mined from Borrowdale in the English Lake District and exported to France. (It was valuable enough that miners at Borrowdale were supervised by armed guards as they changed their clothes at the end of a shift, lest they try to smuggle a nugget away.) But the soft, heat-resistant material was useful not only for pencils but for casting cannonballs, and as military tensions grew between Britain and France, the British put a stop to the flow of graphite across the channel. C’est la vie.

Read’s pencil was more complex than it appeared. How much more complex still is a car, or a computer, or even a toaster? A few years ago, the artist Thomas Thwaites tried to build a no-frills toaster. The result was an oozing mess that cost about $1,000, took months to assemble and, when it was plugged into mains electricity, caught fire. “I realised that if you started absolutely from scratch, you could easily spend your life making a toaster,” Thwaites told me. Yet thanks to the miracle of the market, the toaster was available from Argos with the proceeds of less than an hour’s minimum-wage labour.

Miracle notwithstanding, the Argos toaster had more than 400 components and subcomponents, with an average cost of less than a penny apiece. If the supply of any one of those components dries up, we’re back to eating bread and butter.

This is not just a hypothetical scenario. The production of cars has been constricted by a lack of basic computer chips. The production of vaccines has been threatened by a lack of giant plastic bags. The production of meat has been jeopardised by a lack of carbon dioxide, a side effect of high natural gas prices.

In each case, the kingdom is being lost for want of a horseshoe nail that few even realised existed. Who knew that vaccines needed special bags, or that carbon dioxide was an essential part of the process of turning pigs into pork chops?

The complex world of obscure supply chains is a wonderful curiosity when explained by Leonard E. Read’s pencil. It is less wonderful when the shelves are empty and billions remain unvaccinated. “Have faith that free men and women will respond to the Invisible Hand,” declaims the pencil. Should we?

At 11.38am on January 28 1986, the Space Shuttle Challenger took off from Cape Canaveral in Florida. Seventy-three seconds later, the shuttle broke apart. Seven astronauts died as their cabin crashed into the Atlantic Ocean, and the investigation and recriminations began. The cause of the disaster — as sensationally demonstrated in a televised hearing by the physicist Richard Feynman — was a rubber seal called an O-ring, which had become brittle in unseasonably cold weather. A single failure in a simple component had doomed the mission, and the crew of seven.

The Challenger disaster seems like a tragic one-off. But what if O-ring failures are all around us, not just bringing down spaceships, but causing problems in every aspect of life? The economist Michael Kremer argues that economics should be paying more attention to the way economies work when the whole chain relies on the weakest link.

Reliability costs money, and businesses and their customers will willingly pay for that reliability. But only up to a point. If $1m-worth of production rests on $1,000-worth of computer chips, we should hardly be surprised if the supplier who is being paid $1,000 does not act as if $1m is at stake. When each link of the chain is being outsourced to a different provider, from time to time we will discover that the chain breaks somewhere under the strain.

There are two obvious solutions to this problem. One is to ensure that every link in the chain is made by the same organisation: a single, vertically integrated supplier. The second — far more common in the 21st century — is to ensure more competition at every stage, so that when one link breaks a replacement is at hand. That can work. Indeed, it is the reason why the lights usually stay on and the shelves usually stay well stocked. But if a problem hits a whole industry rather than a single firm, the weak links soon make themselves known.

The general feeling among supply-chain geeks is that while the Christmas rush is sure to cause yet more headaches, the current problems are temporary and somewhat overblown. In March 2020, as Covid-19 spooked shoppers, I spoke to Professor Yossi Sheffi of MIT. He was relaxed. “We are not going to run out of food, so chill,” he told me. He was not wrong. We did not run out of food. We ran out of kettlebells. And civilisations do not collapse because of a shortage of kettlebells.

When I ask Shanella Rajanayagam what surprised her about the current supply-chain strains, she is similarly upbeat. She’d been impressed by how superbly the global economic system is coping given the astonishing range of challenges. “It’s just one thing after another,” she says. “And it’s things beyond Covid-19.”

Global commerce has been strained by a post-lockdown surge in demand from western consumers, flush with cash they have been unable to spend. At the same time, ports have been constricted by Covid-19 restrictions, manufacturing in Vietnam has been held back by a huge outbreak of the Delta variant, truck drivers have been wondering whether the job is worth the hassle and a container ship blocked the Suez Canal for a week. There was a fire in a Japanese chip factory, China closed dozens of coal mines after accidents and safety violations, and months of unfavourable weather have caused a shortage of natural gas. All this has coincided with the pre-Christmas peak in demand for container shipping.

And yet, said Rajanayagam, “supply chains are still resilient. There’s been such a surge in demand for goods, and for the most part it has been provided.”

It is easy to lose sight of that, especially when you can’t buy a tank of petrol. We notice what is missing — but we still have quick and convenient access to a wider range of products than we did 20 years ago. The world trading system has absorbed punch after punch. It’s still standing.

Manufacturers have been moving to a “just-in-time” system of inventory management since the 1950s. To an outsider, “just in time” sounds like cutting things fine, a recipe for chaos. But as Yossi Sheffi explains in The New (Ab)Normal, “just in time” was originally Toyota’s effort to prevent parts shortages by better co-ordinating with suppliers. Smaller inventories were a welcome side effect.

It seems logical to expand those inventories, moving from “just in time” to “just in case”. That is exactly what UK consumers were doing when they all queued to fill up their cars at the same time. In the medium term, larger inventories may be a price worth paying. In the short term, a collective rush to build inventories is disastrous, as manufacturers hoard vital components. But to paraphrase Joseph Heller’s Catch-22, if everyone starts hoarding, then you’d be a damned fool to act any other way.

Governments could take action here and there — for example, to subsidise storage capacity in the energy system, or boost the resilience of the electrical grid. But in many cases, the complexity and the interconnectedness of the supply chains make it hard to see how governments might help.

Perhaps all we can do is to take the pencil’s advice and trust in the invisible hand. With apologies to John Maynard Keynes, at least we can be confident that when the storm is long past, the ocean will be flat again.

But there is one government that will not sit idly by. Instead, it hopes to hoist sails and ensure the maximum possible exposure to the howling economic winds. It is, of course, the government of the UK.

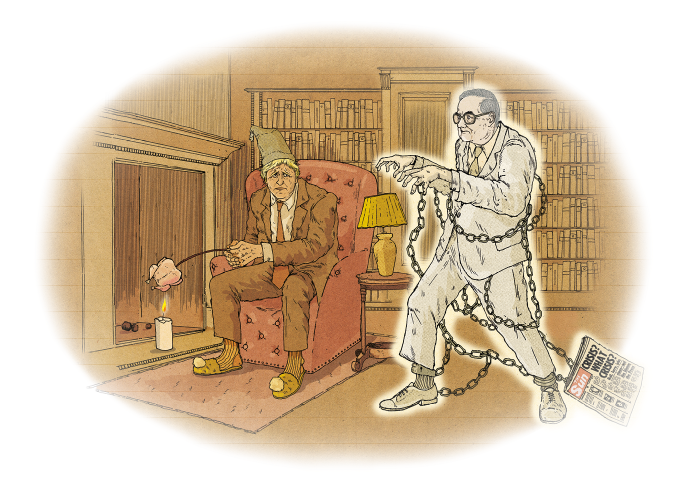

A decade ago, software engineers at Netflix created Chaos Monkey, a system which randomly disables Netflix servers. The idea behind the crazy-sounding scheme was to push Netflix engineers to build more resilient systems. Servers do fail, after all, so it might be best to get some practice in. Having concluded that these random acts of self-sabotage were delivering the desired response, Netflix followed up with Chaos Kong, which simulates a much broader service failure.

Late in 2019, the British people decided that Chaos Kong would make a good prime minister and elected Boris Johnson by a large margin. Johnson has now decided to make a virtue of his own recklessness. After initially claiming that the shortage of truck drivers in the UK was entirely unconnected to Brexit, the government now boasts that the shortage is indeed Brexit-related and was the plan all along. True to the spirit of Chaos Kong, this tough love for the British economy is the only way to get it to shape up.

In preventing the easy recruitment of truck drivers, abattoir workers and care-home staff from the EU, the UK government is actively blocking the most straightforward way to get the economy running smoothly again. (To ensure everyone got the message, Johnson compared immigrants to heroin, complaining that businesses had been able to “mainline low-wage, low-cost immigration”.) The assertion is that if the government deliberately constricts the supply of essential workers, the economy will come out stronger in the long run. Chaos Kong worked for Netflix. Will it work for the UK?

It seems unlikely. In 2018, the government’s independent Migration Advisory Committee surveyed the latest evidence on productivity and immigration. A variety of studies using a variety of methods concluded that immigration was a huge boost to productivity. Indeed, the estimates of the benefits were so large that the MAC couldn’t quite believe them.

That is not to say that the market cannot find a way around any shortage. It can. After the British forbade the supply of graphite to the French, Nicholas-Jacques Conté came to the rescue. Conté was a French army officer, balloonist, adventurer — and pencil engineer. He painstakingly developed a way to make pencil leads from a mix of clay with low-grade powdered continental graphite. The prime minister hopes that British businesses will prove just as innovative in response to the government’s self-imposed barriers to foreign labour.

The problem is that these innovations are not always what one might hope. Faced with a shortage of waiters and cooks, some restaurants will use more frozen, pre-cooked food from factory kitchens. The challenge of recruiting abattoir workers and fruit pickers may be met by dramatically raising wages and improving conditions — or by importing food instead. If we can no longer bring the Latvians to Norfolk turkey farms, Norfolk turkey farms may have to go to Latvia.

The government’s reasoning is particularly questionable when it comes to truck drivers. Truck drivers are in short supply in most western countries, but particularly so in the UK, which until recently was home to tens of thousands of truck drivers from the EU. Thanks to Covid-19, more than a third of them went home, and thanks to post-Brexit restrictions on immigration, they are unlikely to return.

There is no doubt that in the medium term, British truckers will be trained and recruited, probably on substantially improved pay and conditions. But truckers are a small fraction of the workforce, so it is hard to expect much of an effect on pay overall. Meanwhile, how much damage will be done to other businesses in the interim? Can that damage possibly be outweighed by a more prosperous, homegrown trucking industry?

There is one encouraging precedent: US manufacturing in the 1920s. The economic historian Paul David observed that there was a long delay after developing electric motors before they were productively used in manufacturing. Electric motors only fulfilled their potential once production lines were re-engineered, factory buildings redesigned, and workers retrained. This took courage, imagination and about three decades. Electrification caught on in US factories in about 1920 and productivity surged at rates never seen before or since.

What provoked this sudden reorganisation? Perhaps it was just a matter of time. Partly it was enabled by the falling cost and rising availability of power from the electricity grid. But David argued that factory owners rethought their operations once the flow of immigrant workers dried up. More than a million people a year had moved to the US from Europe before the war, but in 1914 this stopped — first because of the war itself, and then because of postwar legislation. Lacking workers, factory owners had to figure out how to get more from less. David concluded that real wages in manufacturing rose sharply along with productivity.

Immigration restrictions alone were not enough; productivity rose because a revolutionary technology lurked in the background. “It was the confluence of these two streams,” wrote David, “that gave the decade of the 1920s its truly extraordinary character.”

Boris Johnson is betting that if he gives the UK economy a shock, something will turn up — just as when you give your television a thump, it might work better. And it might. But Chaos Kong does not seem to have a clear idea of what opportunities might materialise.

It is possible that the result of the chaos will be adaptation, innovation and resilience. But in this case, I am suffering from an acute shortage of optimism.

Follow @FTMag on Twitter to find out about our latest stories first.